|

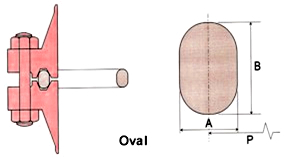

R – STYLE RING JOINT GASKETS (OVAL) |

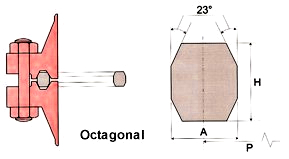

R – STYLE RING JOINT GASKETS (OCTAGONAL) |

|

RX – STYLE RING JOINT GASKETS |

BX – STYLE RING JOINT GASKETS |

|

R (Oval Type) Ring Joint Gasket |

Style R gaskets are manufactured in accordance with both API 6A and ASME B16.20 size/ratings. Available in both oval and octagonal configurations, both types are interchangeable on modern octagonal type grooved flanges.

Style R Ring Joint gaskets can be manufactured in accordance with all relevant standards to suit the following flange designations: API- 6A, ASME/ANSI B16.5, MSS SP44 (ASME B 16.47 Series A) & BS 1560.

Tolerances: ( Inches)

![]() Width of Ring …………………………………±0.008

Width of Ring …………………………………±0.008

![]() Height of Ring ………………………………..±0.020

Height of Ring ………………………………..±0.020

![]() Pitch Diameter………………………………..±0.007

Pitch Diameter………………………………..±0.007

![]() (Octagonal) Angle of 23°………………….±1/2°

(Octagonal) Angle of 23°………………….±1/2°

| STYLE R RING JOINT GASKET DIMENSION TABLE |

| Please click here to download the R Type Ring Joint Gasket Dimension Table. |

| STYLE R SELECTION TABLE |

| NOMINAL PIPE SIZE | PRESSURE CLASSES | ||||||||||||

| ASME B16.5 | API 6B | ASME B16.47 Series A | |||||||||||

| 150# | 300# – 600# | 900# | 1500# | 2500# | 720# – 960# (1) | 2000# | 3000# | 5000# | 10000# | 150# | 300# – 600# | 900# | |

| ½” | – | R-11 | R-12 | R-12 | R-13 | – | – | – | – | – | – | – | – |

| ¾” | – | R-13 | R-14 | R-14 | R-16 | – | – | – | – | – | – | – | – |

| 1” | R-15 | R-16 | R-16 | R-16 | R-18 | R-16 | R-16 | R-16 | R-16 | R-82 | – | – | – |

| 1 ¼” | R-17 | R-18 | R-18 | R-18 | R-21 | R-18 | R-18 | R-18 | R-18 | – | – | – | – |

| 1 ½” | R-19 | R-20 | R-20 | R-20 | R-23 | R-20 | R-20 | R-20 | R-20 | R-84 | – | – | – |

| 2” | R-22 | R-23 | R-24 | R-24 | R-26 | R-23 | R-23 | R-23 | R-24 | R-85 | – | – | – |

| 2 ½” | R-25 | R-26 | R-27 | R-27 | R-28 | R-26 | R-26 | R-26 | R-27 | R-86 | – | – | – |

| 3” | R-29 | R-31 | R-31 | R-35 | R-32 | R-31 | R-31 | R-31 | R-35 | R-87 | – | – | – |

| 3 ½” | R-33 | R-34 | – | – | – | – | – | – | R-37 | R-89 | – | – | – |

| 4” | R-36 | R-37 | R-37 | R-39 | R-38 | R-37 | R-37 | R-37 | R-39 | R-88 | – | – | – |

| 5” | R-40 | R-41 | R-41 | R-44 | R-42 | R-41 | R-41 | R-41 | R-44 | R-90 | – | – | – |

| 6” | R-43 | R-45 | R-45 | R-46 | R-47 | R-45 | R-45 | R-45 | R-46 | – | – | – | – |

| 8” | R-48 | R-49 | R-49 | R-50 | R-51 | R-49 | R-49 | R-49 | R-50 | – | – | – | – |

| 10” | R-52 | R-53 | R-53 | R-54 | R-55 | R-53 | R-53 | R-53 | R-54 | R-91 | – | – | – |

| 12” | R-56 | R-57 | R-57 | R-58 | R-60 | R-57 | R-57 | R-57 | – | – | – | R-57 | R-57 |

| 14” | R-59 | R-61 | R-62 | R-63 | – | R-61 | R-61 | R-61 | – | – | – | R-61 | R-62 |

| 16” | R-64 | R-65 | R-66 | R-67 | – | R-65 | R-65 | R-65 | – | – | – | R-65 | R-66 |

| 18” | R-68 | R-69 | R-70 | R-71 | – | R-69 | R-69 | R-69 | – | – | – | R-69 | R-70 |

| 20” | R-72 | R-73 | R-74 | R-75 | – | R-73 | R-73 | R-73 | – | – | – | R-73 | R-74 |

| 22” | – | – | – | – | – | – | – | – | – | – | R-80 | R-81 | – |

| 24” | R-76 | R-77 | R-78 | R-79 | – | – | – | – | – | – | – | R-77 | R-78 |

| 26” | – | – | – | – | – | – | – | – | – | – | – | R-93 | R-100 |

| 28” | – | – | – | – | – | – | – | – | – | – | – | R-94 | R-101 |

| 30” | – | – | – | – | – | – | – | – | – | – | – | R-95 | R-102 |

| 32” | – | – | – | – | – | – | – | – | – | – | – | R-96 | R-103 |

| 34” | – | – | – | – | – | – | – | – | – | – | – | R-97 | R-104 |

| 36” | – | – | – | – | – | – | – | – | – | – | – | R-98 | R-105 |

|

NOTE: (1) – Class 720, 960, 10000 and 2900 flanges to API 6B are obselete. Data is for informational purposes only. |

|||||||||||||