Joint keys welded on sleeve

Joint keys welded on sleeve

Joint keys welded on pipe

Various types of joint keys

Diyak Ltd. Stabilizer Joints are an another unique product that designed for reasons of economy and to reduce the cost for Stabilizing and centering the pipe. These Stabilizers Joints can use as Stabilizers and as well as Centralizers joints also; they can be welded directly on Pipe and on Sleeve for centralization. In drilling, Rock Bits are designed to rotate about their own centre. Stabilization assures that the bit will do this and thus cause the energies and forces exerted on it to be most efficiently utilized in an axial direction. Without stabilization, rough spiral bores ledges and other unconformity are obtained. The possibilities of crooked hole are enhanced. Drill steel rotating in these rough and crooked bores scrubs and scrapes against the bore wall and thereby abrades. This allows uniform loading and better distribution of explosives in the hole. This means more blasting efficiency and a reduction in secondary blasting. Theoretically, the guiding elements should have the same diameter as the bit. Unfortunately, this is not practical because of the normal attrition of rock bit gauge wear surfaces. The stabilizer should therefore be held at the largest diameter practicable. Concentricity of guiding elements with the axis of the bit and steel is also quite important to proper stabilization. Eccentricities of these elements tend to avoid any hope of reducing drilling costs with a stabilizer. Therefore, the Stabilizer that maintains guiding elements close to hole wall is most efficient.

Therefore, they are available in several lengths and sizes (specially designed Radius on top and bottomof joints) as desired by the customer. These are specially double rolled Alloy Steels bars. This can be welded as per necessity, under required temperature and condition with low Hydrogen Electrodes, which assured ultimate strength and uniformity in every weld. Steel construction provides superior toughness over other materials. Its Insured positive standoff, Maximum flow, Maximum well bore stabilization, Maximum holding strength, decreased drag. They can be choose as per customer requirements, these Joints are much cost effective and very economical as compare to other Centralizers. They can be supply in any chemical composition, in any international grade.

The welding rods recommended for these keys should be Extra Low Hydrogen coated and low temperature. So that deposits exhibit very strength & provide unique resistance to hydrogen induced embrittlement. This can be welded on dirty steel also without porosity or cracking with exceptionally high physical properties. All these keys supply phosphate coated. This deposited Iron Phosphate on Stabilizers Joint that acts as a good bondrizing agent for welding as well as for powder paint and liquid paint. Along with this it makes Stabilizers Joints clears both peel test and Salt Spray test. They are available in 2 7/8”, 3 ½”, 4 ½”, 5 ½”sizes for any hole combination.

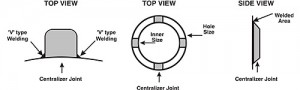

PROCEDURE: Re-dry the electrodes in oven before use. Maintain short to medium arc. Employ, lowest possible current- employ shorts stringer beads. Pre heat upto 200 degree Centigrade in case of Heavy/ dissimilar section for better weldability without porosity or cracking. Welding should be in “V” shape as shown in fig.