In the oil and gas industry, gas lift valves play a crucial role in artificial lift systems, optimizing production by injecting gas into the wellbore to reduce the hydrostatic pressure and enhance oil recovery. At Kriloha Ltd, we specialize in providing high-quality oilfield products, including industrial seals, chevron seals, chevron packing, and vee packing seals, ensuring superior performance and durability in gas lift valve operations.

In this blog, we will explore the function, types, and benefits of gas lift valves and how Kriloha Ltd’s premium sealing solutions enhance their efficiency.

What is a Gas Lift Valve?

A gas lift valve is a crucial component in gas lift systems, which are used in oil production to artificially lift crude oil from the wellbore to the surface. It operates by injecting high-pressure gas into the well tubing, reducing the fluid column’s density and enabling the oil to flow more efficiently.

Key Functions of Gas Lift Valves:

Regulating gas injection into the well.

Optimizing production rates by reducing hydrostatic pressure.

Enhancing well performance in declining pressure conditions.

Ensuring efficient fluid flow in both offshore and onshore wells.

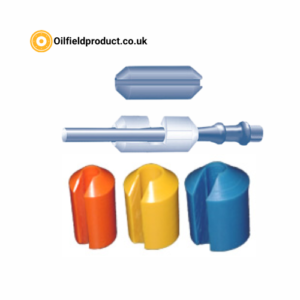

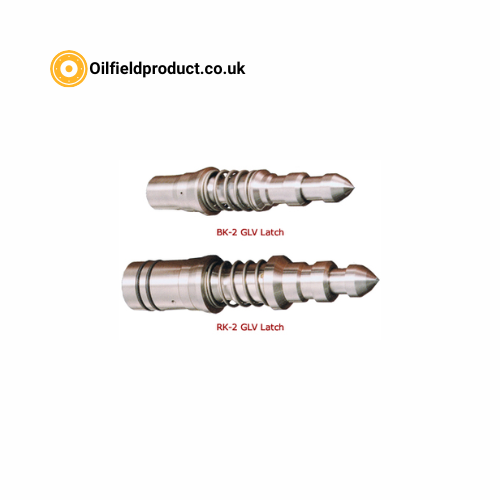

Types of Gas Lift Valves

Different gas lift valve types are used in oilfield operations based on well conditions and production goals. Below are the most common ones:

1. Pressure-Operated Gas Lift Valves

These valves function based on tubing and casing pressures. Features include:

Automatic opening and closing depending on pressure changes.

Efficient gas injection control to optimize oil production.

Sealing integrity enhanced with chevron seals and industrial seals.

2. Bellows-Type Gas Lift Valves

These valves use a bellows mechanism to regulate gas injection. Their advantages include:

High durability under fluctuating pressures.

Excellent sealing performance with chevron packing and vee packing seals.

Ideal for deep-well applications.

3. Orifice Gas Lift Valves

Orifice valves have a fixed gas injection opening and offer:

Constant gas flow for consistent production.

Minimal maintenance requirements.

Long-lasting operation with high-performance industrial seals.

Enhancing Gas Lift Valve Performance with Kriloha Ltd’s Sealing Solutions

The efficiency of gas lift valves largely depends on the quality of sealing components. Kriloha Ltd provides top-quality chevron seals, chevron packing, vee packing seals, and industrial seals that enhance the durability and performance of gas lift valves.

1. Chevron Seals

Chevron seals play a crucial role in gas lift valves by:

Providing exceptional leak-proof performance.

Handling extreme pressures in oil wells.

Ensuring reliable gas lift operations.

2. Chevron Packing

Chevron packing improves the efficiency of gas lift valves by:

Enhancing resistance against gas pressure fluctuations.

Preventing leaks for optimized production.

Ensuring extended operational life.

3. Vee Packing Seals

Vee packing seals are ideal for gas lift applications due to:

High adaptability to varying pressure conditions.

Improved sealing under dynamic movement.

Enhanced durability in extreme environments.

4. Industrial Seals

Industrial seals from Kriloha Ltd provide:

Superior wear resistance for extended valve life.

Exceptional performance in harsh oilfield conditions.

Customizable solutions for different gas lift applications.

Benefits of Using High-Quality Gas Lift Valves and Seals

By integrating Kriloha Ltd’s premium oilfield products into your gas lift systems, you gain numerous advantages:

Increased Oil Recovery – Enhancing production rates with efficient gas injection.

Improved Well Performance – Ensuring consistent fluid flow and pressure control.

Enhanced Safety – Preventing leaks and system failures with reliable sealing solutions.

Long-Term Durability – Reducing maintenance and operational costs.

Optimized Efficiency – Maximizing production with high-quality components.

Why Choose Kriloha Ltd for Gas Lift Valve Sealing Solutions?

At Kriloha Ltd, we are dedicated to supplying top-tier sealing solutions for gas lift valves and other oilfield products. Here’s why industry professionals trust us:

High-Quality Sealing Components – Offering superior chevron seals, chevron packing, vee packing seals, and industrial seals.

Customized Solutions – Tailored to meet unique operational needs.

Unmatched Durability – Designed for extreme oilfield conditions.

Expert Support – Providing guidance on the best sealing solutions for your equipment.

Conclusion

Gas lift valves are essential in oilfield production, enabling efficient oil recovery by reducing hydrostatic pressure through gas injection systems. By incorporating Kriloha Ltd’s premium sealing solutions, including chevron seals, chevron packing, vee packing seals, and industrial seals, oil and gas companies can significantly enhance valve performance and extend equipment life.

For high-performance gas lift valves and sealing solutions, contact Kriloha Ltd today and explore our range of oilfield products designed for superior efficiency and durability.