In the oil and gas industry, sealing solutions play a crucial role in ensuring operational safety, efficiency, and reliability. Among these, Ring Joint Gaskets (RTJ gaskets) are highly preferred for high-pressure and high-temperature applications in pipelines, refineries, and offshore drilling platforms. At Kriloha Ltd, we specialize in providing high-quality oilfield products, including industrial seals, chevron seals, chevron packing, and vee packing seals, designed to enhance the performance of critical sealing applications like RTJ gaskets.

In this blog, we will explore the importance, types, and benefits of Ring Joint Gaskets, along with the role of Kriloha Ltd’s advanced sealing solutions in optimizing their efficiency.

What are Ring Joint Gaskets?

Ring Joint Gaskets (RTJ gaskets) are precision-engineered metallic gaskets used in high-pressure oil and gas applications. These gaskets are commonly used in:

Wellhead equipment

Drilling and production platforms

Pipeline flanges

Valve and pressure vessel connections

Refineries and petrochemical plants

Designed for metal-to-metal sealing, RTJ gaskets provide exceptional leak-proof performance under extreme conditions.

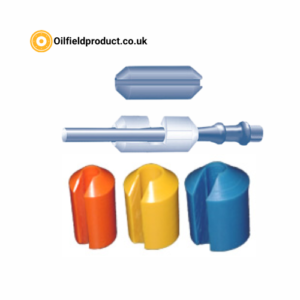

Types of Ring Joint Gaskets

1. Oval Ring Joint Gaskets

These gaskets have an oval cross-section and are designed for API 6A and ASME B16.5 flange connections.

Good sealing capabilities under fluctuating pressures.

High durability in harsh environments.

Effective use of chevron seals for enhanced sealing.

2. Octagonal Ring Joint Gaskets

With an octagonal cross-section, these gaskets provide better sealing performance than oval types.

Increased surface contact for a tighter seal.

Ideal for high-temperature applications.

Chevron packing and vee packing seals improve sealing efficiency.

3. BX Ring Joint Gaskets

BX gaskets are designed for API 6BX flanges, ensuring leak-tight performance under extreme conditions.

Handles high-pressure environments up to 20,000 psi.

Compatible with oilfield products requiring robust sealing.

Reinforced with industrial seals for extended lifespan.

4. RX Ring Joint Gaskets

RX gaskets are pressure-energized and offer superior sealing capabilities.

Self-sealing under increasing pressure conditions.

Ideal for offshore oil rigs and refineries.

Supports applications with vee packing seals for added strength.

Benefits of Ring Joint Gaskets in Oil & Gas Applications

Ring Joint Gaskets provide several advantages in oilfield operations, including:

Leak Prevention – Ensures zero leakage under extreme pressure conditions.

High Temperature Resistance – Withstands high temperatures without deforming.

Corrosion Resistance – Made from materials like stainless steel and Inconel for longevity.

Reliable Performance – Ideal for critical sealing applications in oil refineries, pipelines, and drilling equipment.

Compliance with Industry Standards – RTJ gaskets meet API, ASME, and ISO regulations.

Enhancing RTJ Gasket Performance with Kriloha Ltd’s Sealing Solutions

The durability and efficiency of Ring Joint Gaskets are significantly improved with high-quality sealing components. At Kriloha Ltd, we provide premium chevron seals, chevron packing, vee packing seals, and industrial seals to enhance the performance of RTJ gaskets.

1. Chevron Seals

Enhance gasket longevity by preventing leaks.

Resist high-pressure and high-temperature conditions.

Ensure tight sealing in oilfield applications.

2. Chevron Packing

Provides flexibility to handle pressure fluctuations.

Improves the efficiency of gaskets in drilling operations.

Offers superior resistance to oil, gas, and chemicals.

3. Vee Packing Seals

Reinforce the sealing capability of RTJ gaskets.

Designed to withstand dynamic movement in oilfield equipment.

Extend the service life of critical sealing applications.

4. Industrial Seals

Ensure reliability in high-pressure environments.

Prevent wear and tear of gaskets under extreme conditions.

Provide custom sealing solutions tailored to oilfield needs.

Why Choose Kriloha Ltd for Ring Joint Gaskets and Sealing Solutions?

At Kriloha Ltd, we are committed to delivering top-quality sealing solutions for the oil and gas industry. Here’s why industry professionals trust us:

Superior Material Quality – Our industrial seals, chevron seals, chevron packing, and vee packing seals are designed for durability.

Customized Solutions – Tailored to meet specific sealing requirements.

Reliability & Performance – Designed to withstand extreme oilfield conditions.

Industry Expertise – Years of experience in sealing solutions for high-pressure applications.

Conclusion

Ring Joint Gaskets are essential components in oil and gas operations, ensuring leak-proof performance in high-pressure environments. By integrating Kriloha Ltd’s premium sealing solutions, including chevron seals, chevron packing, vee packing seals, and industrial seals, companies can enhance the efficiency, durability, and reliability of their RTJ gaskets.

For high-performance Ring Joint Gaskets and sealing solutions, contact Kriloha Ltd today and explore our range of oilfield products designed for superior efficiency and durability.