In the oil and gas industry, sealing solutions play a crucial role in ensuring the safety and efficiency of equipment. Among the most reliable sealing options are Otis and Baker Vee Packing, designed for high-pressure applications in oilfield products such as valves, pumps, and blowout preventers. These sealing solutions provide exceptional durability, leak resistance, and longevity, making them indispensable for oilfield operations.

At Kriloha Ltd, we specialize in high-performance industrial seals, including chevron seals, chevron packing, and vee packing seals, tailored for demanding oilfield applications.

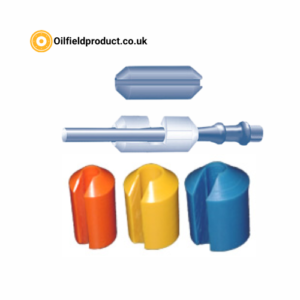

Understanding Otis and Baker Vee Packing

What is Vee Packing?

Vee packing seals are multi-lip seals made of flexible materials designed to withstand extreme pressure, temperature variations, and harsh drilling environments. Otis and Baker Vee Packing are industry-leading sealing solutions used in hydraulic cylinders, pumps, and wellhead equipment to prevent fluid leaks and maintain operational integrity.

Why are Otis and Baker Vee Packing Seals Preferred?

Superior Pressure Resistance: Designed for high-pressure applications in oilfield products.

Leak Prevention: Ensures a secure seal in hydraulic and pneumatic systems.

Wear and Tear Resistance: Withstands extreme operational conditions.

Extended Equipment Lifespan: Protects vital components from damage.

Applications of Otis and Baker Vee Packing in Oilfield Products

1. Blowout Preventers (BOPs)

Blowout Preventers rely on vee packing seals to maintain pressure control and prevent well blowouts.

2. Valves and Pumps

Oilfield valves and pumps require durable sealing solutions to prevent leaks under extreme pressure.

3. Downhole Tools

Drilling and completion tools depend on Otis and Baker Vee Packing to maintain proper pressure control.

Industrial seals resist oil, gas, and extreme temperatures.

Chevron packing maintains sealing efficiency in deep drilling environments.

Advantages of Using Otis and Baker Vee Packing

1. Exceptional Sealing Performance

Designed for high-pressure and high-temperature environments, vee packing seals provide excellent sealing capabilities.

2. Versatility Across Oilfield Applications

These seals are used in BOPs, valves, pumps, actuators, and wellhead equipment, making them a versatile choice for oilfield products.

3. Durability and Cost-Effectiveness

By reducing the risk of equipment failure, Otis and Baker Vee Packing minimize downtime and maintenance costs.

4. Enhanced Compatibility with Chevron Packing

Combining vee packing seals with chevron packing enhances sealing efficiency, ensuring superior pressure retention in oilfield equipment.

Why Choose Kriloha Ltd for Otis and Baker Vee Packing?

At Kriloha Ltd, we are dedicated to providing high-quality oilfield products and sealing solutions that meet the rigorous demands of the oil and gas industry.

Our Key Offerings:

Premium Quality Chevron Seals: Designed for extreme drilling environments.

High-Performance Industrial Seals: Resistant to harsh oilfield conditions.

Durable Chevron Packing: Extends equipment lifespan and improves performance.

Reliable Vee Packing Seals: Optimized for hydraulic and pneumatic applications.

Conclusion

Otis and Baker Vee Packing are essential sealing solutions for oilfield equipment, offering superior pressure resistance, leak prevention, and durability. At Kriloha Ltd, we provide top-quality industrial seals, chevron seals, chevron packing, and vee packing seals, ensuring optimal performance and safety in oilfield operations.

For premium sealing solutions, contact Kriloha Ltd today and explore our range of high-performance oilfield products.