In the oil and gas industry, ensuring leak-proof connections in high-pressure fluid transfer systems is crucial. One of the most reliable sealing solutions in these applications is the Hammer Union Seal. These seals play a vital role in maintaining pressure integrity in pipelines, manifolds, and wellhead equipment. At Kriloha Ltd, we specialize in high-performance oilfield products, including industrial seals, chevron seals, chevron packing, and vee packing seals, ensuring the longevity and reliability of Hammer Union Seals.

What is a Hammer Union Seal?

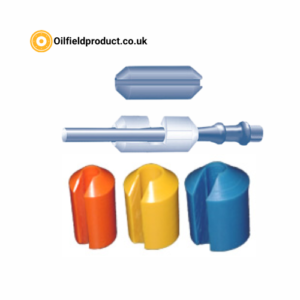

A Hammer Union Seal is a specialized gasket designed to provide a tight, leak-proof seal in high-pressure hammer union connections. These seals are commonly used in drilling, fracking, and well-servicing operations, where pipelines and manifolds must withstand extreme pressure and harsh environments.

Key Functions of Hammer Union Seals:

Prevent fluid leaks in high-pressure applications.

Enhance the durability of hammer unions.

Resist extreme temperatures, pressure, and aggressive chemicals.

Ensure reliable sealing in oilfield pipelines, wellheads, and fracking operations.

Applications of Hammer Union Seals in Oilfield Products

1. Wellhead Equipment

Hammer Union Seals are used in wellhead assemblies to ensure pressure integrity and fluid control.

Chevron seals improve sealing performance in high-pressure environments.

Industrial seals enhance resistance to oil, gas, and extreme temperatures.

2. Drilling and Fracking Operations

Oilfield drilling and hydraulic fracturing require durable seals to prevent leaks under high-pressure conditions.

3. Manifolds and Pipeline Connections

Hammer Union Seals play a key role in maintaining leak-proof pipeline and manifold connections.

Types of Hammer Union Seals

1. Elastomer Hammer Union Seals

Made from rubber compounds such as Nitrile, Viton, and HNBR.

Ideal for dynamic sealing applications where flexibility and elasticity are required.

2. Metal-Reinforced Hammer Union Seals

3. PTFE Hammer Union Seals

Advantages of Hammer Union Seals

1. Superior Leak Prevention

Hammer Union Seals ensure zero fluid leakage, enhancing safety and operational efficiency.

2. High-Pressure and Temperature Resistance

These seals are designed to withstand extreme drilling conditions, making them ideal for oilfield applications.

3. Durability and Longevity

With premium materials such as chevron packing and industrial seals, these seals offer extended service life, reducing maintenance costs.

4. Enhanced Compatibility with Chevron Seals

Integrating chevron seals with Hammer Union Seals improves sealing efficiency, particularly in high-pressure oilfield operations.

Why Choose Kriloha Ltd for Hammer Union Seals?

At Kriloha Ltd, we provide high-quality oilfield products, including industrial seals, chevron seals, chevron packing, and vee packing seals, ensuring reliable performance in demanding oil and gas environments.

Our Key Offerings:

Premium-Quality Chevron Seals: Designed for extreme pressure and temperature conditions.

High-Performance Industrial Seals: Resistant to oil, gas, and corrosive drilling fluids.

Durable Chevron Packing: Ensures long-lasting sealing solutions in hammer union connections.

Reliable Vee Packing Seals: Optimized for hydraulic and pneumatic applications.

Conclusion

Hammer Union Seals are essential components in oilfield operations, providing superior sealing performance in drilling, fracking, and well-servicing applications. At Kriloha Ltd, we offer top-quality industrial seals, chevron seals, chevron packing, and vee packing seals, ensuring the reliability and efficiency of oilfield equipment.

For premium sealing solutions, contact Kriloha Ltd today and explore our range of high-performance oilfield products.