Blowout Preventers (BOPs) are critical safety components in oilfield drilling operations. Ensuring their functionality through rigorous testing is not just a precaution—it’s a necessity. At Kriloha Ltd, we provide high-performance BOP Cup Testers as part of our extensive line of oilfield products, designed to uphold safety, precision, and efficiency in demanding drilling environments.

In this blog, we’ll explore the features, applications, and benefits of BOP Cup Testers and their synergy with essential components like chevron seals, industrial seals, chevron packing, and vee packing seals.

What is a BOP Cup Tester?

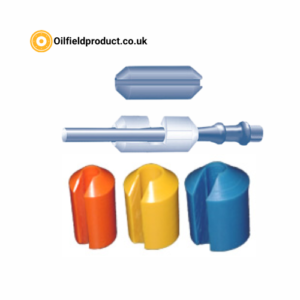

A BOP Cup Tester is a specialized tool used to pressure test the ram or annular blowout preventer (BOP) by sealing against the internal diameter of the BOP bore. This is essential to ensure the integrity and performance of BOP systems before and during drilling operations.

BOP Cup Testers are equipped with a durable rubber cup and robust mandrel body to seal effectively and withstand extreme pressure.

Features of Kriloha’s BOP Cup Testers

High-pressure resistance for annular and ram-type BOPs

Heavy-duty elastomer cups that form a secure seal

Customizable sizes for different BOP specifications

Corrosion-resistant materials for long-term usage

Easy handling and installation for operational efficiency

Importance in Oilfield Operations

Testing BOPs is a mandatory operation in drilling to prevent catastrophic blowouts. BOP Cup Testers ensure:

Reliable pressure integrity before drilling commences

Compliance with international safety standards

Enhanced operational safety

Prevention of unexpected equipment failure

As a core part of oilfield products, these testers significantly contribute to a safe and efficient drilling environment.

Elastomer Excellence in Cup Testers

The effectiveness of a BOP Cup Tester largely depends on the quality of the elastomer used. Kriloha Ltd uses special elastomers also found in our sealing products, including:

Chevron seals

Chevron packing

Vee packing seals

Industrial seals

Elastomer Properties:

Resistance to oil-based and water-based drilling fluids

High tensile strength

Excellent memory and flexibility

Withstand high-pressure, high-temperature (HPHT) conditions

Integration with Chevron Seals & Vee Packing

BOP Cup Testers don’t function in isolation. They work alongside critical sealing systems:

1. Chevron Seals

Also known as chevron packing, these V-shaped rings provide reliable pressure sealing under dynamic conditions.

Used extensively in BOP actuators to maintain seal integrity under pressure cycles.

2. Vee Packing Seals

3. Industrial Seals

Benefits of Kriloha’s BOP Cup Testers

Safety First

Proper testing with our BOP Cup Testers ensures the highest safety standards in drilling operations.

Durability

Made with top-tier materials and industrial seals, our testers offer long-term, reliable performance.

Efficiency

Simplified installation and minimal maintenance reduce rig downtime and testing delays.

Compatibility

Fully compatible with a range of BOP designs and easily integrates with chevron seals and vee packing seals for holistic system performance.

Customization

Available in various sizes and elastomer compositions to meet client-specific drilling requirements.

Applications Across the Oil & Gas Industry

Our BOP Cup Testers are used in:

Onshore and offshore rigs

Exploration and production wells

Routine maintenance and pre-drill inspections

High-pressure testing in extreme environments

Their ability to operate under challenging conditions makes them indispensable among oilfield products.

Why Choose Kriloha Ltd?

At Kriloha Ltd, we’re committed to delivering excellence in every product. Our BOP Cup Testers reflect our dedication to:

From chevron packing to BOP Cup Testers, Kriloha is your trusted partner for robust oilfield products designed to excel under pressure.

Innovations and Future Outlook

As the oil and gas industry continues to evolve, so does our product line:

Smart Testers with digital pressure monitoring are in development

Enhanced elastomer blends for extended service life

Eco-friendly manufacturing practices to support sustainability

Kriloha continues to push the boundaries of oilfield innovation while ensuring safety and reliability in every product we offer.

Conclusion

BOP Cup Testers are vital tools that play a significant role in safeguarding oilfield operations. When integrated with reliable sealing solutions like chevron seals, vee packing seals, and industrial seals, they provide unparalleled performance.

Backed by Kriloha Ltd’s commitment to quality and innovation, our BOP Cup Testers ensure your drilling operations stay safe, compliant, and efficient.