Insulation Kit Gaskets

Insulation Kit Gaskets: The Ultimate Corrosion Protection Solution for Oilfield Products

In the oil and gas industry, flange integrity plays a vital role in ensuring the safety, efficiency, and longevity of pipeline systems. One of the biggest threats to these systems is galvanic corrosion, especially when dissimilar metals are joined together. To combat this, Insulation Kit Gaskets have become the industry standard for reliable sealing and long-lasting protection.

At Oil Field Products, we provide a wide range of Flange Insulation Kit Gaskets engineered with precision to deliver superior performance in even the harshest environments.

What Are Insulation Kit Gaskets?

Insulation Kit Gaskets are specially designed components that electrically isolate two flanges in a piping system. By doing so, they prevent stray electrical currents from passing between dissimilar metals, which often leads to galvanic corrosion.

- These gaskets are typically made from non-conductive materials such as phenolic resin or fiberglass.

- They not only seal the flanges but also insulate the joint, ensuring that no electrochemical reactions occur that could damage pipelines.

This makes them essential for systems where cathodic protection is employed, particularly in subterranean pipelines and oilfield infrastructure

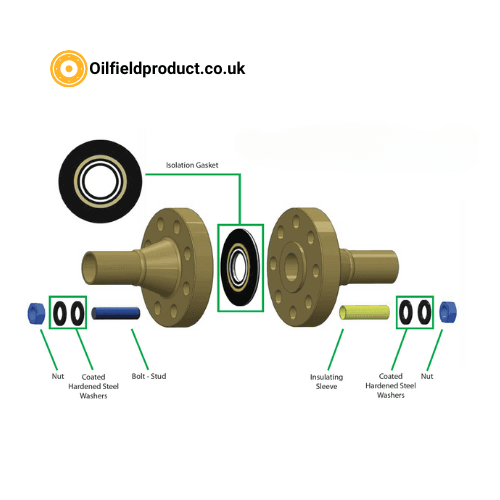

What Does a Complete Insulation Kit Include?

A standard insulation kit from leading engineers typically consists of:

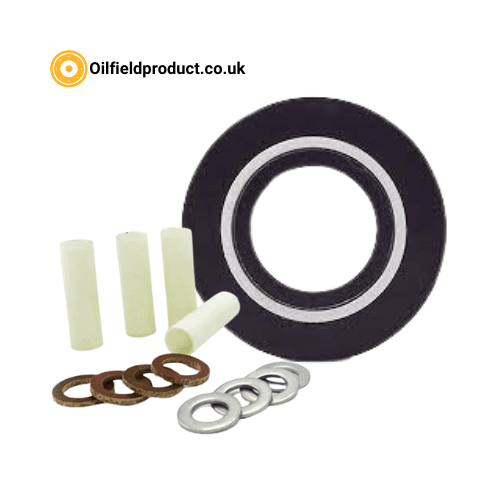

- Insulation Kit Gaskets – The main gasket that isolates and seals the flange connection.

- Insulating Sleeves for Bolts – These prevent current from flowing through flange bolts and also help distribute stress evenly during tightening.

- Insulating Washers – These provide additional protection against conductivity through bolt holes, ensuring the entire flange joint is electrically isolated.

Together, these components form a comprehensive barrier against corrosion while maintaining a reliable mechanical seal.

Types of Insulation Kit Gaskets

At Oil Field Products, we supply all major types of Flange Insulation Kit Gaskets, suitable for ANSI, API, BS, and DIN standards. Each type is designed for specific flange applications:

Type "F" Insulation Gaskets (For Raised Face Flanges)

- Designed for raised face flanges, with the gasket fitting inside the flange bolt circle.

- The gasket rests on the raised face portion of the flange, ensuring a tight seal.

- Available in a variety of durable materials, these gaskets are versatile and widely used across oilfield operations.

Type "E" Insulation Gaskets (For Full Face Flanges)

- Designed for full face flanges with a gasket outer diameter equal to the flange’s outside diameter.

- Precision-cut bolt holes make installation simple and reliable.

- Manufactured using materials such as Neoprene-faced reinforced phenolic, these gaskets offer both strength and easy alignment.

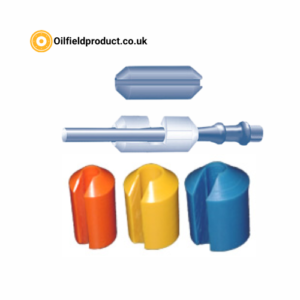

Type "D" Insulation Gaskets (For Ring Gaskets)

- Commonly used with ring-type joints (RTJ flanges).

- Manufactured from fabric-reinforced phenolic, available in both oval and octagonal designs.

- Compliant with ASME B-16.20 standards, Type D gaskets deliver robust sealing performance in demanding oilfield environments.

Key Benefits of Using Insulation Kit Gaskets

- Superior Corrosion Protection – Prevents galvanic corrosion caused by dissimilar metals.

- Extended Equipment Lifespan – Protects critical pipeline systems, reducing costly maintenance.

- Leak Prevention – Ensures reliable sealing in high-pressure environments.

- Cost Savings – Reduces downtime and extends the life of flanged connections.

- Compliance with Industry Standards – Available in ANSI, API, BS, and DIN specifications.

Applications Across Industries

While widely used in oilfield pipelines, insulation kit gaskets are also essential in:

- Petrochemical plants

- Offshore and onshore platforms

- Refineries

- Gas distribution systems

- Power generation facilities

Wherever long-term sealing and corrosion protection are required, insulation kit gaskets are indispensable.

Why Choose Oil Field Products for Insulation Kit Gaskets?

At Oil Field Products, our Flange Insulation Kits are engineered for precision, durability, and performance. By sourcing high-quality materials and adhering to international standards, we ensure our clients benefit from reliable corrosion protection and long-lasting sealing solutions.

Whether you need Type F, Type E, or Type D insulation gaskets, we provide a complete range designed to meet your specific operational needs.

The oil and gas industry cannot afford the risks of flange failure due to galvanic corrosion. Insulation Kit Gaskets are not just a protective measure—they are an investment in the safety, efficiency, and reliability of your entire operation.

At Oil Field Products, we offer a complete line of Insulating Flange Kits to meet global industry standards. From preventing leaks to extending equipment life, our gaskets are the trusted choice for professionals worldwide.

Get in Touch Today

Contact Oil Field Products today to request a quote or speak with our technical experts

Materials Used

| Insulation Gasket | Insulation Sleeve | Insulation Washer | Plated Washer | |

| Standard | Neoprene faced Phenolic | Reinforced Phenolic | Reinforced Phenolic | Electro platedsteel washer |

| Special | Neoprene faced Phenolic | Nylon | Nylon | |

| Neoprene faced Phenolic | Mineral filled Nylon | Mineral filled Nylon | ||

| Neoprene faced Phenolic | Polyethylene | Polyethylene | ||

| Glass Reinforced Epoxy (G-10) | Glass Reinforced Epoxy (G-10) | Glass Reinforced Epoxy (G-10) | ||

| PTFE | PTFE | PTFE | ||

| G11 | Glass Reinforced Epoxy (G-10) | Glass Reinforced Epoxy (G-10) |

Properties of materials used in Flange Insulation Gaskets kits

| Material | Dilectric Strength (Volts / MIL) | Water Absorption (%) | Max.Cont. OperatingTemp. (Deg.C.) |

| Polyethylene | 450 | 0.01 | 41 |

| Phenolic | 400-500 | 1.1 | 107 |

| Nylon | 457 | 1.5 | 110 |

| G10 | 550 | 0.01 | 138 |

| G11 | 550 | 0.01 | 177 |

| PTFE | 450 | 0.01 | 41 |