Equipment Gaskets

Equipment Gaskets for Oil Field Products: Reliable Sealing Solutions for Industrial Excellence

In today’s demanding oil and gas industry, the importance of reliable sealing solutions cannot be overstated. From heat exchangers and boilers to columns and autoclaves, every piece of equipment relies on precision-engineered gaskets to maintain safety, efficiency, and leak-free operation. Without the right gasket in place, even the most advanced systems risk downtime, contamination, and costly failures.

At Oil Field Products, we provide a wide range of equipment gaskets that meet the highest industry standards, ensuring dependable performance under extreme operating conditions.

Why Equipment Gaskets Are Critical in Oilfield Operations

Oilfield environments are characterized by high pressure, fluctuating temperatures, and corrosive fluids. A gasket’s job is to maintain a secure seal between flanges, preventing leaks while withstanding vibration, chemical exposure, and intense stress.

When selecting the right gasket, engineers must consider factors such as:

- Type of media (oil, gas, steam, chemicals, etc.)

- Flange type and condition

- Operating pressure and temperature

- Vibration levels and environmental conditions

- Long-term durability and reusability

The right gasket not only ensures leak-free performance but also prolongs equipment life, reduces downtime, and boosts overall system efficiency.

Types of Equipment Gaskets We Provide

At Oil Field Products, our gasket portfolio includes solutions for heat exchangers, flue stacks, pumps, columns, autoclaves, and more. We specialize in three major categories of equipment gaskets:

Heat Exchanger Gaskets

Heat exchangers are vital in oilfield operations, transferring heat between fluids while keeping them separate. To maintain efficiency, heat exchanger gaskets prevent fluid leaks and cross-contamination.

These gaskets are manufactured using a range of materials, including:

- Rubber – Flexible, cost-effective sealing.

- PTFE – High chemical resistance.

- Graphite – Excellent for high temperatures.

- Metal composites – Designed for durability and strength.

Proper gasket selection is essential to avoid reduced heat transfer efficiency and equipment damage.

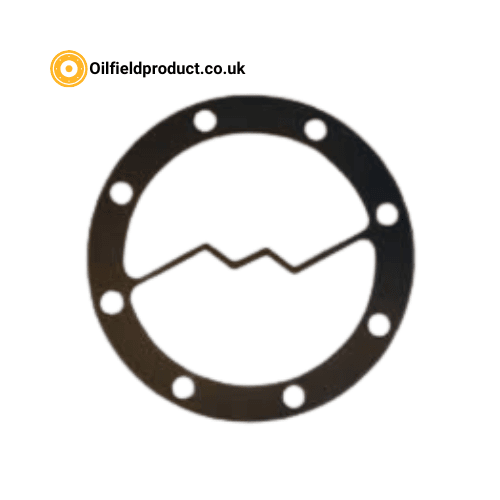

Metal Jacketed Gaskets

- Construction: A soft compressible core (non-asbestos fillers or graphite) encased in a metal jacket (stainless steel, carbon steel, copper, Monel, Inconel, etc.).

- Applications: Ideal for smooth flange surfaces in heat exchangers, boilers, autoclaves, pumps, gas mains, and valve bonnets.

- Advantages: Withstand extreme pressure/temperature, protect against chemical attack, and ensure reliable sealing.

- Custom Options: Double-jacketed designs with various filler materials (PTFE, Grafoil, Non-asbestos).

Metal Jacketed Gaskets are a versatile solution for high-demand applications, offering both strength and adaptability.

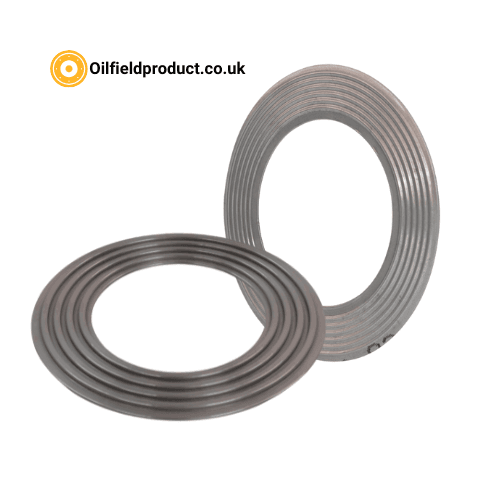

Corrugated Metal Gaskets

- Design: A unique wavy or ridged surface increases contact area, enabling the gasket to conform to flange irregularities.

- Applications: Suited for high-temperature and high-pressure conditions in heat exchangers and columns.

- Benefits: Strong sealing capability, cost-effective, and in some cases reusable if undamaged after removal.

Corrugated Metal Gaskets are the go-to solution for industries seeking robust, reusable, and reliable sealing performance.

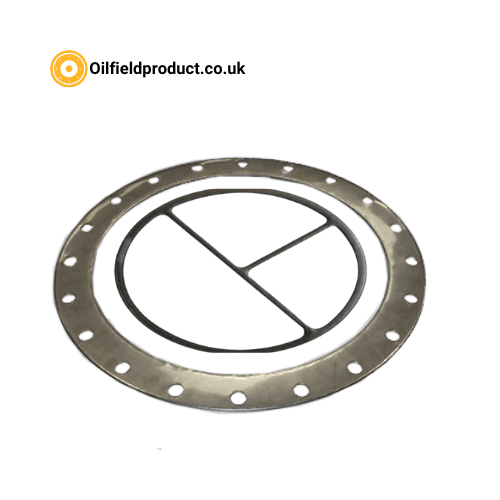

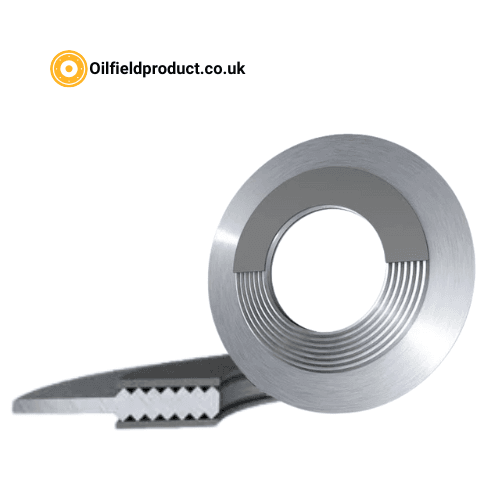

Kammprofile Gaskets

Kammprofile gaskets combine a solid metal core with a soft sealing layer (such as graphite, PTFE, or mica).

- Strengths: Excellent load-bearing capacity, high blowout resistance, and exceptional sealing performance.

- Applications: Used in heat exchangers, pressure vessels, and pipelines where fluctuating pressures and temperatures occur.

- Advantages: High safety factor and longer lifespan compared to traditional gaskets.

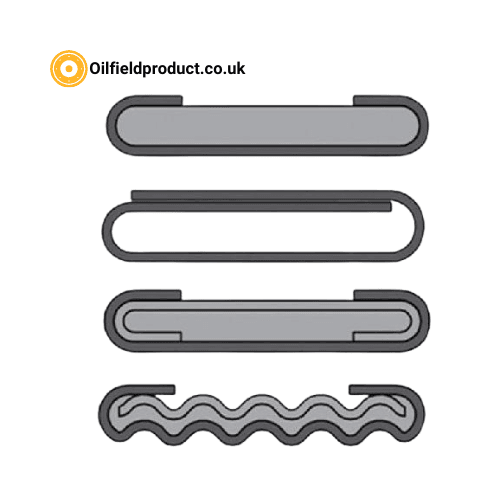

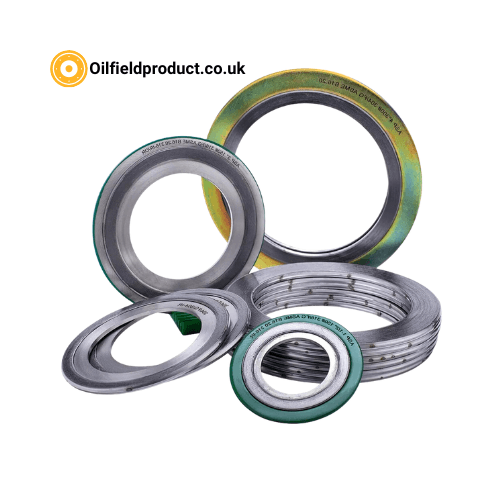

Spiral Wound Gaskets

Spiral wound gaskets are among the most widely used sealing solutions in the oil and gas industry.

- Construction: Made from alternating layers of metal (stainless steel, Inconel) and filler material (graphite, PTFE, or non-asbestos fillers).

- Applications: Excellent for pipelines, valves, pumps, and flanges exposed to superheated steam, extreme pressure, and corrosive media.

- Benefits: Flexible, strong, and capable of handling severe conditions while maintaining long-term reliability.

Advantages of Equipment Gaskets from Oil Field Products

✔ Leak Prevention – Ensures safe and efficient operation under extreme stress.

✔ Corrosion Resistance – Protects against aggressive chemicals and fluids.

✔ Temperature & Pressure Tolerance – Withstands superheated steam, cryogenic conditions, and high loads.

✔ Extended Service Life – Reduces replacement costs and downtime.

✔ Compliance with Standards – Meets ANSI, API, DIN, and other global specifications.

Applications Across Oilfield Equipment

Our equipment gaskets are widely used in:

- Heat exchangers

- Boilers & steam systems

- Oil refineries & petrochemical plants

- Offshore & onshore rigs

- Columns, pumps, and autoclaves

Wherever industrial sealing is required, our gaskets deliver unmatched reliability.

Why Choose Oil Field Products?

At Oil Field Products, we go beyond supplying gaskets—we deliver engineered sealing solutions tailored to your equipment’s exact needs. Our manufacturing expertise ensures precision, durability, and compliance with international quality standards.

From metal jacketed heat exchanger gaskets to spiral wound and Kammprofile gaskets, we provide solutions that keep your operations running safely and efficiently.

Oilfield operations demand the highest level of reliability. With the right equipment gaskets, you safeguard your assets, reduce maintenance costs, and maximize performance.

Oil Field Products is your trusted partner for sealing excellence, offering heat exchanger gaskets, spiral wound gaskets, and Kammprofile solutions that meet the toughest industry challenges.