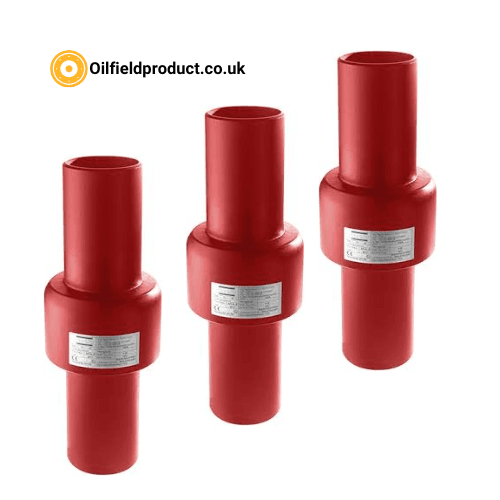

Monolithic Insulation Joints (MIJ)

Monolithic Insulation Joints (MIJ): Advanced Pipeline Protection for Oilfield Applications

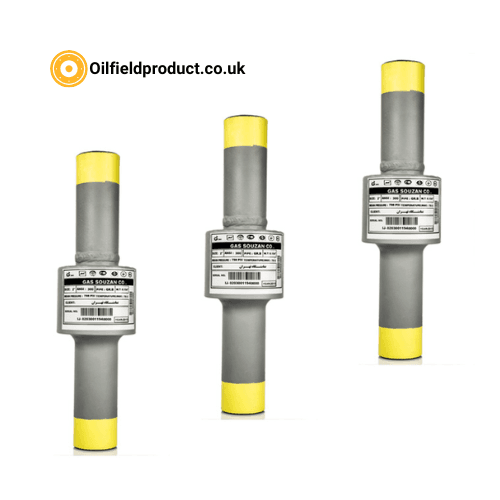

In modern oil and gas operations, protecting pipelines from corrosion and ensuring long-term reliability is a top priority. Among the most advanced solutions available today are Monolithic Insulation Joints (MIJ)—a revolutionary, boltless technology that delivers superior sealing, isolation, and cathodic protection efficiency.

At Oil Field Products, we have been manufacturing and supplying world-class Monolithic Insulating Joints for over two decades, providing unmatched reliability across some of the most critical energy projects in India and around the globe.

What Are Monolithic Insulation Joints?

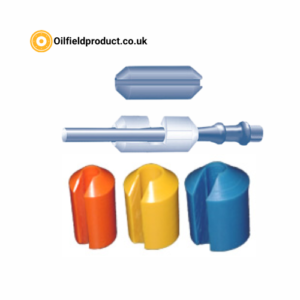

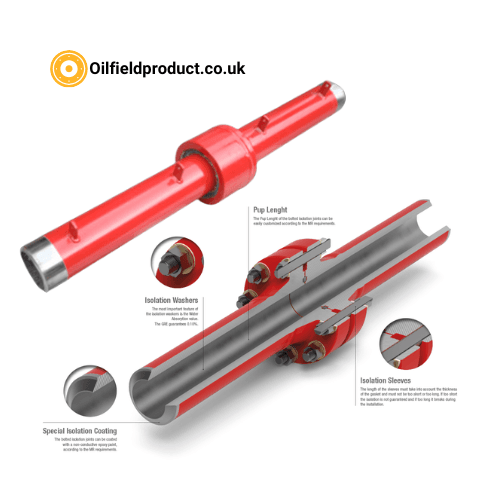

Monolithic Insulating Joints (MIJ) are factory-assembled, boltless isolation joints designed to section off main pipelines. Their primary purpose is to:

• Enhance cathodic protection systems

• Prevent underground corrosion

• Provide a permanent, maintenance-free solution for pipeline insulation

Unlike traditional flange insulation kits, MIJs are designed as a single welded unit, making them tamper-proof, stronger, and longer-lasting.

Why Oil Field Products MIJs Stand Out

Oil Field Products’ MIJs are manufactured and tested in compliance with the strictest global standards, including NACE, ASME, API, and Shell specifications. With proven performance across decades of service, our products are trusted by leading oil and gas companies worldwide.

Key highlights:

• Track Record of Excellence – Over 20 years of field-proven reliability in global energy projects.

• Specialized Materials – Expertise in Alloy 625 & 825 weld overlay (cladding) for sour service applications.

• Underground Applications – Advanced coatings equivalent to 3LPE for buried pipelines.

• Customized Engineering – MIJs designed to exact client specifications for size, rating, materials, and service applications.

Stringent Quality Assurance

Every MIJ we produce is backed by a robust quality assurance program, compliant with:

• ISO-9001:2015 (Quality Management)

• ISO-14001:2015 (Environmental Management)

• ISO-45001:2018 (Occupational Health & Safety)

We also deploy an in-house computerized verification program to confirm the mechanical strength of each joint, ensuring compliance with:

• ASME Sec VIII Div.1, App.2

• ASME B31.3 (Process piping)

• ASME B31.4 (Liquid transmission)

• ASME B31.8 (Gas transmission)

This guarantees that our MIJs meet both international codes and custom client requirements.

Rigorous Testing for Maximum Reliability

At Oil Field Products, every MIJ undergoes extensive testing before delivery to ensure it can withstand the harshest oilfield conditions.

Standard Testing Includes:

• Hydrostatic & Pneumatic Tests – To validate pressure resistance.

• Fatigue Tests – To measure performance under cyclic loads.

• Non-Destructive Examination (NDE) – To confirm integrity without damaging the unit.

• Electrical Testing – Insulation Resistance (1000 V DC) and Di-electric Strength (up to 5000 V at 50 Hz AC).

Specialized Testing Includes:

• Helium Leak Test – Detects even microscopic leaks.

• Holiday Test – Identifies insulation discontinuities.

• Adhesion Test – Ensures bonding strength of insulating materials.

• Flange Displacement Test – Confirms durability under flange movement.

This multi-stage testing ensures every MIJ performs flawlessly under real-world operating conditions.

Materials That Ensure Performance

To withstand diverse oilfield environments, we carefully select materials that guarantee durability and insulation:

• Pipe Materials: API 5L, ASTM A312 Stainless Steels, IS3589, Duplex Steels (ASTM/ASME/DIN)

• Sealing Materials: FFKM, FKM (Viton), NBR, HNBR, EPDM, PTFE (ASTM D2000)

• Insulating Materials: ASTM D709 & D695 compliant

This material versatility allows us to tailor MIJs to specific service applications, from sour service environments to buried pipeline protection.

Why Choose Oil Field Products?

With decades of expertise, cutting-edge manufacturing, and proven reliability, Oil Field Products has become a global leader in Monolithic Insulation Joints. From major oil companies to pipeline contractors, our clients trust us to deliver durability, safety, and performance in every joint.

Information Required for Inquiry

When requesting a quotation for Monolithic Insulation Joints, please provide:

• Size and pressure rating

• Pup piece details

• Materials for body, pup, and insulating material

• Design and test pressures

• Operating temperature

• Service application details

• Installation location (aboveground or buried)

• Desired quantity

This allows us to engineer precisely tailored MIJs that fit your project’s needs.