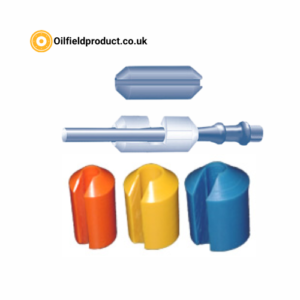

– Precision-forged from high-strength alloy steel- Designed for resilience in HPHT environments- Hardfaced sealing surfaces for erosion resistance- Compatible with FLS-R gate valve assemblies

– FLS-R gate valves- Oil & gas wellhead applications- Offshore drilling platforms- Production and pipeline valves

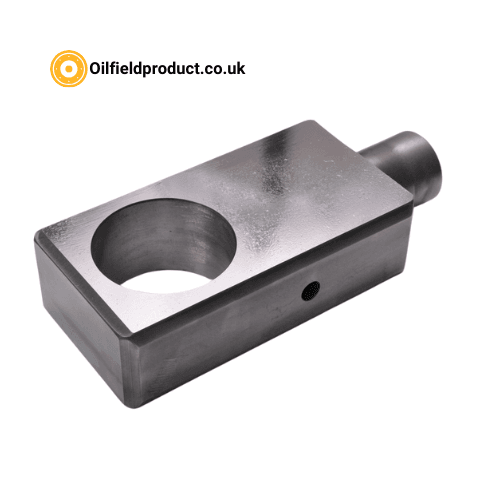

Material Specification: Wrought 410 low alloy steel+Tungsten Carbide

API 6A,PSL1-4

Temperature Ratings :K,L,P,S,T,U,V

Material Class:AA,BB,CC,DD-NL,EE-NL,FF-NL

API Designation 75K,197-237HBW

Size:7″ Inch

Working Pressure: 5.000-15.000 psi