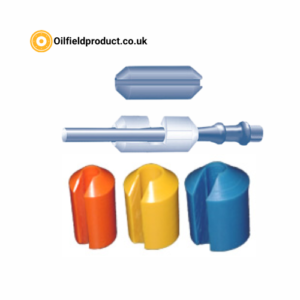

- Coiled Tubing Tools

- Wireline Tools & Accessories

- Completion Equipment

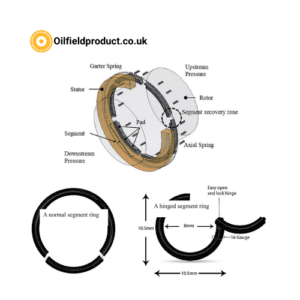

- Flow Control Equipment

- Gas Lift Equipment

- Calibration Of Gaslift Valves

- Gate Valves, Choke Manifolds, Wellheads, X-Mas Trees

- Tubulars, Drilling & Workover Tools, Cementing Equipment