– High-strength, corrosion-resistant alloys- Precision sealing surfaces- Resistant to erosion and abrasive wear- Long-term durability in HPHT environments

– Style FLS gate valves- High-pressure and high-temperature operations- Production and drilling manifolds- Offshore and subsea systems

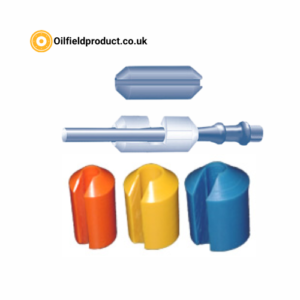

Material Specification: Wrought 410 low alloy steel +Tungsten Carbide

API 6A,PSL 1-4

Temperature Ratings:K,L,P,S,T,U,V

Material Class:AA ,BB,CC,DD-NL,EE-NL,FF-NL

API Designation 75K,197-237 HBW

Size:1″ – 6″ Inch

Working Pressure: 2.000-15.000 psi