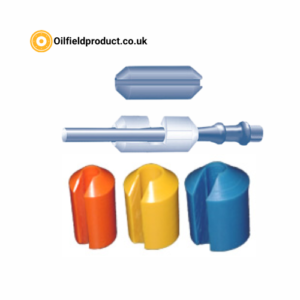

Jetting Dispensing valve has easily interchangeable PEEK nozzle inserts, as well as PEEK fluid inlet fittings, PEEK fluid body, PEEK fluid housing are for anaerobic adhesives. Thereby making it customizable for different application requirements. The PEEK wetted parts (parts that are in contact with the media) are free of metal and separated from the actuator and therefore grant fast and easy serviceability and maintenance.

Piezoelectric jetting technology has greatly improved efficiency and consistency in the manufacture of the complex products emerging from the microelectronics, medical, and automotive industries. The intersection of piezoelectric jetting technology with the modular, exchangeable dispense jet valve creates a whole new dynamic in manufacturing flexibility and versatility.

PolyEtherEtherKetone (PEEK)

Maintains wear resistance and mechanical strength up to 260℃ continuous use.

PEEK is the performance material of choice for aggressive environments such as high temperatures, wet processes, and heavy loads. It combines exceptional wear, chemical and moisture resistance with very high strength, dimensional stability and stiffness. PEEK can be continuously exposed to hot water or steam with no distortion, corrosion or galling.

Unreinforced PEEK is a general purpose material noted for its high elongation and toughness. Glass fiber-reinforced PEEK offers increased strength, stiffness and stability at high temperatures, while carbon fiber-reinforced PEEK gives designers the benefit of excellent compression strength and stiffness and reduced expansion rates. PEEK is easily machined to precise tolerances.

| Properties | Applications | Industries |

| · Superior wear resistance and dimensional stability to 260℃ continuous use · Excellent resistance to chemicals, steam and hydrolysis · Very low moisture absorption · Very high thermal stability (V-O UL 94 rating) · Superb flexural and torsional strength · Abrasion resistant · Good dielectric properties · Good resistance to radiation · Self-extinguishing | · Sliding and wear parts · Food contact parts · Gears · Valve seats · Pump wear parts · Structural parts · Appliance parts · Bushings, bearings, seals and rings · Plug connectors · Wafer carriers | · Chemical technology · Mechanical engineering · Energy industry · Electronics · Food technology · Oil and gas industry · Aircraft and aerospace technology · Automotive industry · Semiconductor technology · Vacuum technology |