• Permanent Installation: Designed for a secure, long-term, and reliable installation that can withstand extreme pressure and temperature differentials.

• Hydraulic Set: Set by applying tubing pressure, providing a simple, safe, and reliable setting mechanism that is ideal for deviated and horizontal wellbores.

• High-Strength Slips: Features two opposed sets of full-circle, full-strength slips that ensure the packer remains securely set in any grade of casing, including premium grades.

• Metal Backup Rings: The packer’s sealing system is backed by unique, interlocking, expandable metal rings that prevent the elastomer from extruding under extreme pressure, providing a secondary barrier and enhancing the packer’s long-term integrity.

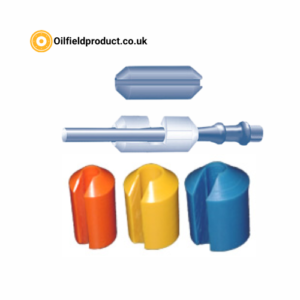

• Slim-Line Design: A compact and slim-line design that allows for faster run-in times without the fear of impact damage or premature setting, saving significant rig time.

• High-Pressure, High-Temperature (HPHT) Wells: The ideal choice for completions in demanding HPHT environments where long-term zonal isolation is critical.

• Permanent Zonal Isolation: Used for long-term separation of production zones, water injection zones, or other wellbore fluid management applications.

• Deviated and Horizontal Wells: The hydraulic setting mechanism makes it the preferred permanent packer for complex well geometries where mechanical setting is not practical.

• Cementing Operations: Can be used as a primary or secondary isolation barrier for multi-stage cementing operations.