PA66 GF30 is a 30 % glass fibre reinforced PA66. It has outstanding mechanical properties such as higher strength, rigidity, creep strength and dimensional stability. Compared to unreinforced PA66, the properties of this glass filled modification GF30 make this material suitable for use in parts that are exposed to high static loads over long periods in high temperature conditions.

Application Areas

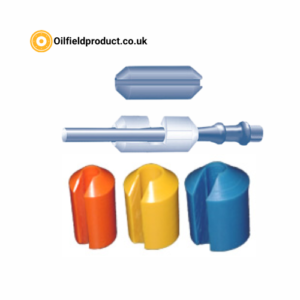

- Rail transport system – Rail Insulator

- Automobile industry – Cable protection parts for vehicles, sector, covers, frames, Reinforcing elements, Radiator cowl, Gear lever housing, Fans / Frames, Gears

- Electrical and electronic – Socket, Insulator, Precision electrical parts

- Mechnical Equipment – Insulating washers, turbines on ships. Propeller shaft, propeller, sliding bearing, Gears

PA66 GF30 Datasheet

| Typical values at 23°C 1) | Test method | Unit | Condition | Values |

| Properties | ||||

| Abbreviated term | ISO 1043 | – | – | PA66-GF30 |

| Density | ISO 1183 | g/cm3 | – | 1.36 |

| Viscosity number (solution 0.005 g/ml sulfuric acid) | ISO 307 | ml/g | – | 145 |

| Colour: natural (n), coloured (c), black (bk) | – | – | – | n,bk |

| Water absorption, equilibrium in water at 23°C | ISO 62 | % | – | 5.20 – 5.80 |

| Moisture absorption, equilibrium 23°C/50% r.h. | ISO 62 | % | – | 1.50 – 1.90 |

| Processing | ||||

| Melting temperature, DSC | ISO 3146 | °C | – | 260 |

| Melt volume rate MVR 275/5 | ISO 1133 | cm3/10 min | – | 40 |

| Melt temperature, injection moulding/extrusion | – | °C | – | 280 – 300 |

| Mould temperature, injection moulding | – | °C | – | 80 – 90 |

| Moulding shrinkage, constrained 6) | – | % | – | 0.55 |

| Flammability | ||||

| UL94 rating at 1.6 mm thickness | UL 94 | class | – | HB |

| Automotive materials (thickness d ≥ 1mm) | FMVSS 302 | – | – | + |

| Mechanical properties | ||||

| Tensile modulus | ISO 527-2 | MPa | dry/cond. | 10000/7200 |

| Yield stress (v = 50 mm/min), Stress at break (v = 5 mm/min)* | ISO 527-2 | MPa | dry/cond. | 190*/130* |

| Yield strain (v = 50 mm/min) | ISO 527-2 | % | dry/cond. | |

| Nominal strain at break, Strain at break* | ISO 527-2 | % | dry/cond. | 3.0*/5.0* |

| Tensile creep modulus, 1000 h, strain £ 0.5%, +23°C | ISO 899-1 | MPa | cond. | 5300 |

| Flexural modulus | ISO 178 | MPa | dry/cond. | 8600/6500 |

| Flexural strength | ISO 178 | MPa | dry/cond. | 280/210 |

| Charpy unnotched impact strength 3) +23°C | ISO 179/1eU | kJ/m2 | dry/cond. | 85/100 |

| Charpy unnotched impact strength -30°C | ISO 179/1eU | kJ/m2 | dry | 70 |

| Charpy notched impact strength 3) +23°C | ISO 179/1eA | kJ/m2 | dry/cond. | 13.0/22.0 |

| Charpy notched impact strength -30°C | ISO 179/1eA | kJ/m2 | dry | 10.0 |

| Izod notched impact strength 1A 3) +23°C | ISO 180/1A | kJ/m2 | dry/cond. | 11.5/15.5 |

| Izod notched impact strength 1A -30°C | ISO 180/1A | kJ/m2 | dry | |

| Ball indentation hardness H 358/30, H 961/30* | ISO 2039-1 | MPa | dry/cond. | 240*/190* |

| Thermal properties | ||||

| Deflection temperature 1.8 MPa (HDT A) | ISO 75-2 | °C | – | 250 |

| Deflection temperature 0.45 MPa (HDT B) | ISO 75-2 | °C | – | 250 |

| Max. service temperature (short cycle operation) 2) | – | °C | – | 240 |

| Temperature index at 50% loss of tensile strength after 20000 h / 5000 h | IEC 216-1 | °C | – | 145 / 175 |

| Thermal coefficient of linear expansion, longitudinal / transverse (23-80)°C | DIN 53752 | 10-4/K | – | 0.2 – 0.3 / 0.6 – 0.7 |

| Thermal conductivity | DIN 52 612 | W(m · K) | – | 0.35 |

| Specific heat capacity | – | J(kg · K) | – | 1500.00 |

| Electrical properties | ||||

| Dielectric constant at 1 MHz Dissipation factor at 1 MHz | IEC 60250 IEC 60250 | – 10-4 | dry/cond. dry/cond. | 3.5/5.6 140/3000 |

| Volume resistivity | IEC 60093 | Ω · m | dry/cond. | 1013/1010 |

| Surface resistivity | IEC 60093 | Ω | dry/cond. | 1012/1010 |

| CTI, solution A | IEC 60112 | – | cond. | 450 |