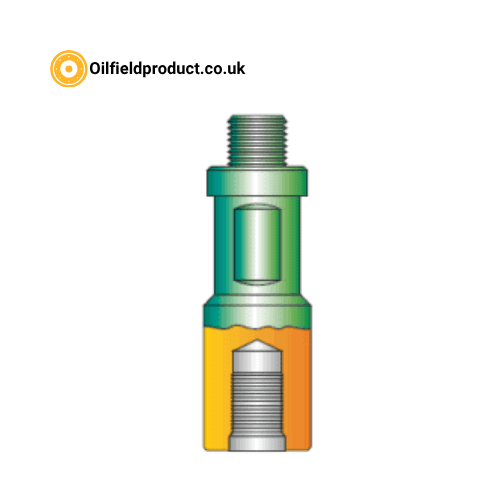

• Single-Grip, Mechanical Set: Set by a simple 1/4 right-hand turn and applied weight. It features a single set of slips that hold the packer from above, making it ideal for applications with pressure from the production zone.

• Large By-Pass: A large internal by-pass is a key feature, allowing for rapid fluid equalization during run-in and retrieval, reducing the swabbing effect and increasing operational efficiency.

• Tubing Pressure Actuated Collet Lock: This feature eliminates the need for excessive set-down weight to maintain the pack-off, as tubing pressure is used to engage a collet lock, providing a secure setting.

• Simple Release: The packer is released by simply picking up the tubing string, which opens the by-pass and releases the slips. The J-slot mechanism automatically resets to the running position.

• Interchangeable Components: The design allows for interchangeable parts with other manufacturers, which can help reduce inventory costs and simplify logistics for operators with mixed fleets of equipment.

• Low-Pressure Conventional Completions: Ideal for wells where the pressure differential is from below the packer, such as in low-pressure production zones.

• Well Testing: A reliable choice for temporary zonal isolation during well testing and evaluation.

• Perforating Operations: Used to provide a stable anchor for the tubing string during perforating, especially when the well is expected to flow after perforating.

• As an Upper Packer: Can be used as an upper packer in dual or multi-packer completions where the primary seal is provided by a lower packer.